Storage small class-penfa chemical industry

Storage small class-penfa chemical industry,

Calcium Formate, Calcium Formate Manufacturers, Calcium Formate Suppliers, China Calcium Formate, manufacturers calcium formate,

1. Basic information of calcium formate

Molecular formula: Ca(HCOO)2

Molecular weight: 130.0

CAS NO: 544-17-2

Production capacity: 60,000 tons/year

Packaging: 25kg paper-plastic composite bag

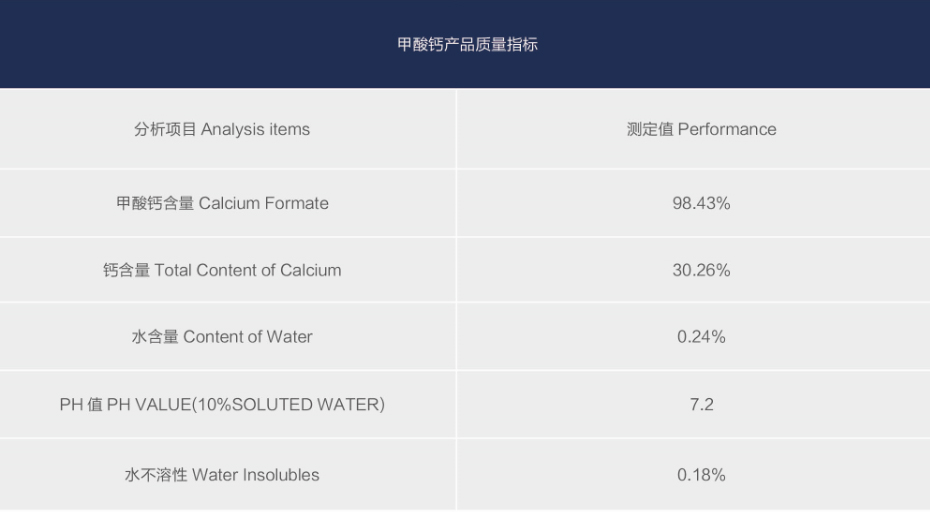

2. Product quality index of calcium formate

3. Application scope

1. Feed grade calcium formate: 1. As a new type of feed additive. Feeding calcium formate to gain weight and using calcium formate as a feed additive for piglets can promote the appetite of piglets and reduce the rate of diarrhea. Adding 1% to 1.5% calcium formate to the piglet diet can significantly improve the performance of weaned piglets. A German study found that adding 1.3% calcium formate to the diet of weaned piglets can improve the feed conversion rate by 7% to 8%, and adding 0.9% can reduce the incidence of piglet diarrhea. Zheng Jianhua (1994) added 1.5% calcium formate to the diet of 28-day-old weaned piglets for 25 days, the daily gain of piglets increased by 7.3%, the feed conversion rate increased by 2.53%, and the protein and energy utilization rate increased by 10.3% respectively. and 9.8%, piglet diarrhea was significantly reduced. Wu Tianxing (2002) added 1% calcium formate to the diet of ternary hybrid weaned piglets, the daily gain was increased by 3%, the feed conversion rate was increased by 9%, and the piglet diarrhea rate was reduced by 45.7%. Other things to note are: the use of calcium formate is effective before and after weaning, because the hydrochloric acid secreted by the piglets increases with age; calcium formate contains 30% easily absorbed calcium, so pay attention to adjusting calcium and phosphorus when formulating feed. proportion.

2. Industrial grade calcium formate:

(1) Construction industry: as a quick-setting agent, lubricant and early-drying agent for cement. It is used in construction mortar and various concretes to speed up the hardening speed of cement and shorten the setting time, especially in winter construction, to avoid too slow setting speed at low temperature. The demoulding is fast, so that the cement can be put into use as soon as possible.

(2) Other industries: tanning, wear-resistant materials, etc.Acid storage notes 1, stored in a cool, ventilated bin temperature. Keep away from kindling and heat source, avoid direct sunlight, pay attention to personal protection when loading and handling. Light handling should be done to prevent damage to packaging and containers. 2. Emergency Treatment: quickly evacuate the personnel from the spill-contaminated area to the safe area and isolate them, and strictly restrict their access. Emergency personnel are advised to wear self-contained positive pressure breathing apparatus and acid and alkali resistant overalls. Don’t come into direct contact with the spill. Don’t let the spill come into contact with organic matter, reducing agents, combustibles. Cut off the source of the leak if you can. Prevent access to restricted spaces such as sewers, storm drains, etc. Small leakage: adsorption or absorption by sand or other noncombustible materials. You can also sprinkle the floor with soda ash, then rinse it with plenty of water, dilute it with washing water and put it in a wastewater system. Mass leakage: construction of an embankment or pit for containment; covering with foam to reduce steam hazards. Spray water cools and dilutes steam. Transfer by pump to a tank car or special collector for recovery or transport to a waste disposal site for disposal.